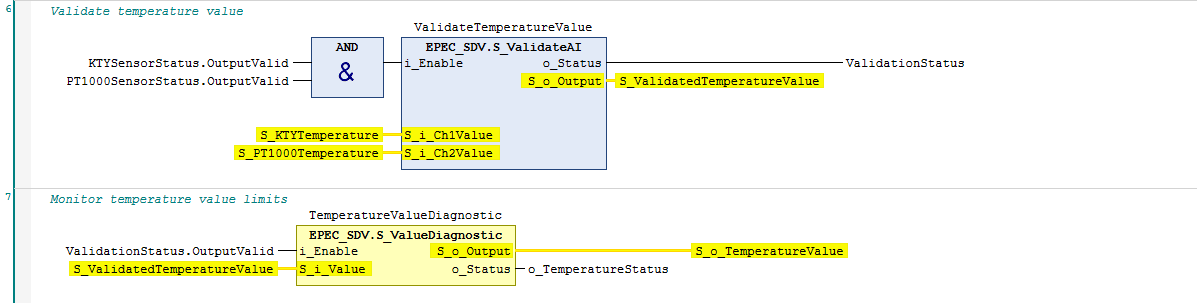

The readings must be converted to temperature values before validation. Valid temperature is then limit checked.

|

|

This example uses the following libraries: SafeConversion library SafeSensorCalibration library

SafeDataValidation library

|

|

|

S_ADCToVoltageOrCurrent POU is included in the code template generated by MultiTool Creator.

|

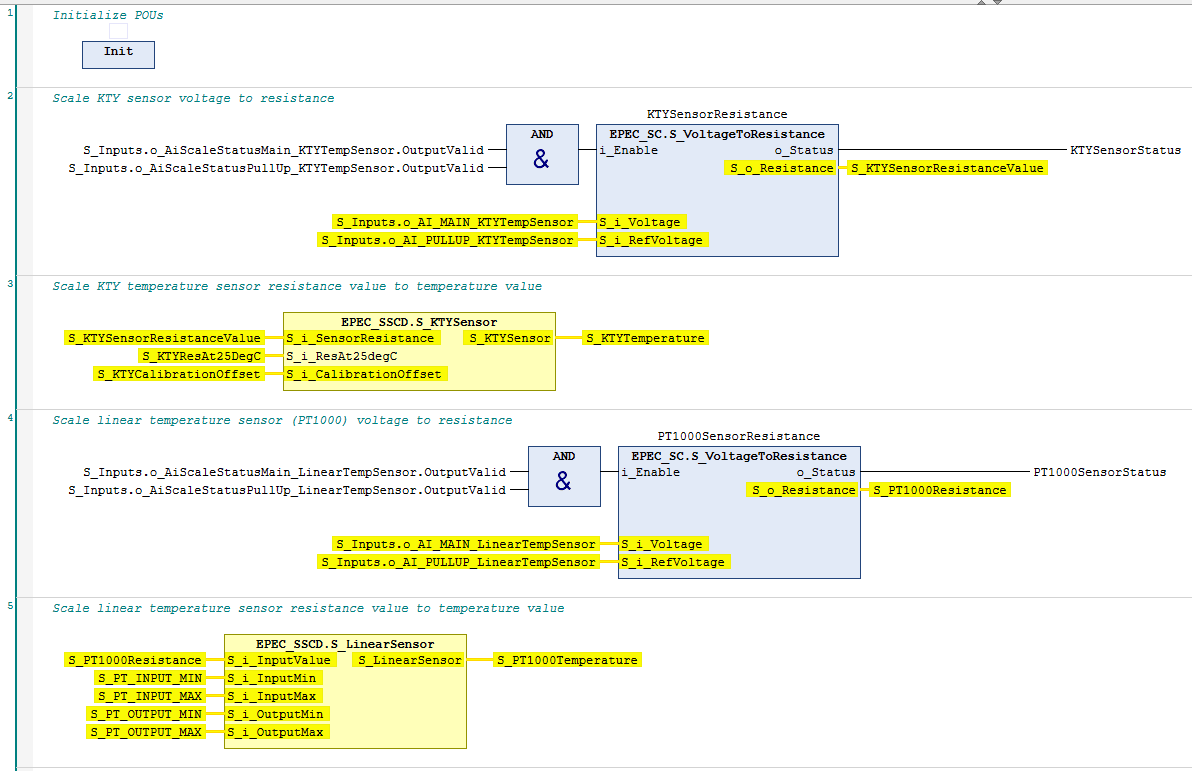

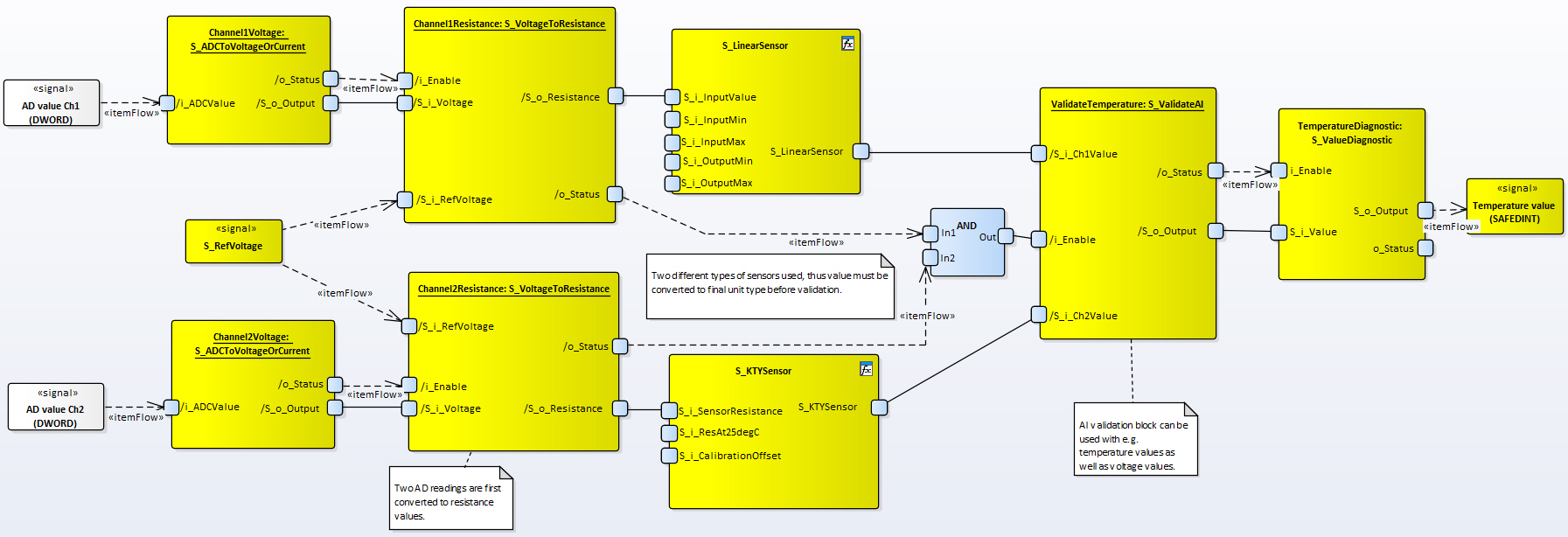

The following image is an architecture example for temperature sensor validation.

S_RefVoltage in the example image is the measured supply voltage for the input.

MultiTool code template provides pull-up measurement for AI pins (for products where they are available).

Example code

The following example demonstrates temperature reading of two safety related AIs, KTYTempSensor and LinearTempSensor defined in MultiTool Creator.

|

|

When the following example is used with non-safety I/O, the I/O variables are generated in Inputs program instead of S_Inputs. |

|

|

Pull-up to 5 V is selected in MultiTool Creator's AI configuration when using resistance sensors.

|

|

|

This example is implemented with AI mode where resistance conversion is not included in code template. With TI mode the resistance conversion is included in code template and can be omitted from application code. TI mode is not supported by all products.

|

|

|

Example implementation is made with SC52 unit which has pull-up measurement available. For products which does not have AI pull-up measurement (e.g. SL84), use hardcoded 5000 mV value for voltage to resistance conversion's S_i_RefVoltage.

// SL84 does not have pull-up measurements, assume 5V pullup S_TEMP_PULLUP_VOLTAGE: SAFEDINT := DINT#5000; |

|

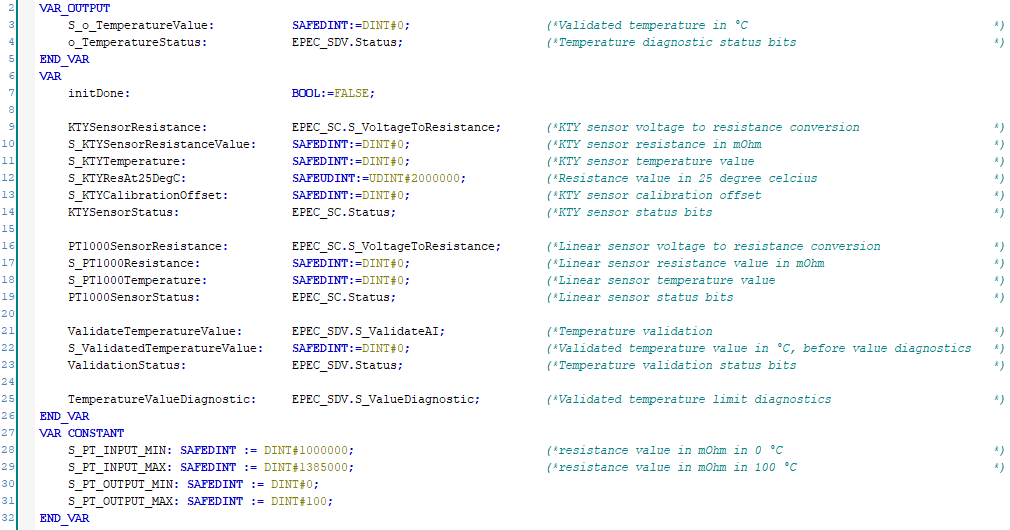

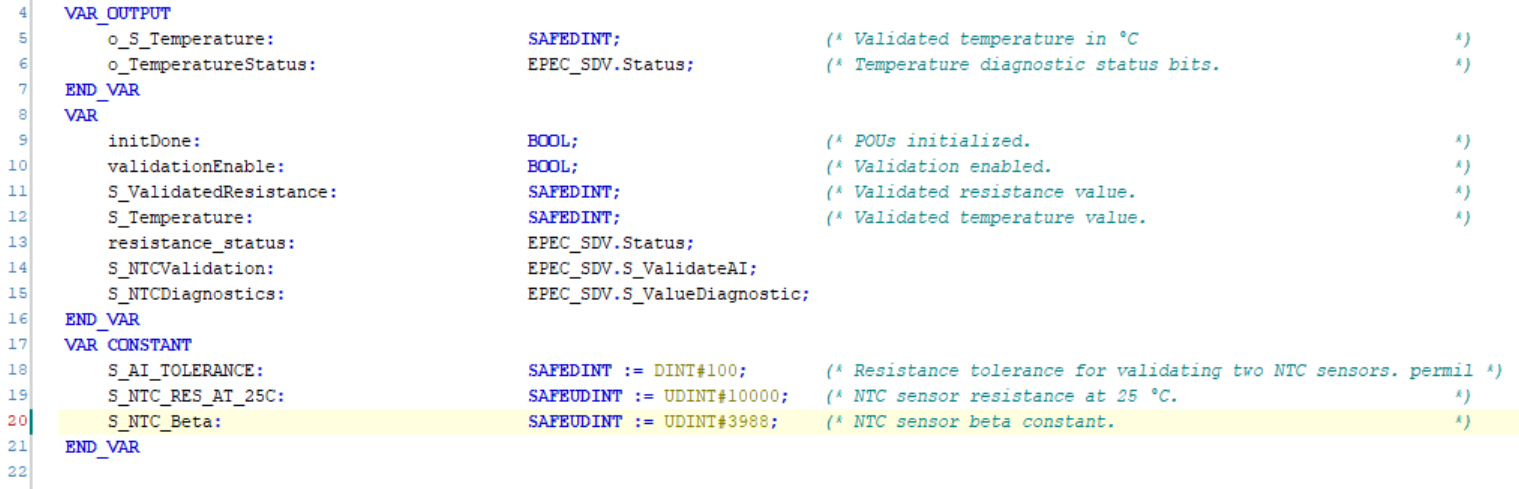

Safe PRG:

|

|

|

Initialization

|

Init method:

IF NOT initDone THEN initDone:=TRUE;

KTYSensorResistance.Init( S_i_InternalPullUpResistance:=EPEC_HW.PULL_UP_RESISTANCE.R_2K2 , S_i_InternalPullDownResistance:=EPEC_HW.PULL_DOWN_RESISTANCE.R_82K , S_i_OutputResistanceHigh:=DINT#4500 , S_i_OutputResistanceLow:=DINT#1000 , S_i_DiagnosticDelay:=UINT#1000 , i_pEventCode:= ADR(S_Inputs.o_EventCodeMain_KTYTempSensor));

PT1000SensorResistance.Init( S_i_InternalPullUpResistance:=EPEC_HW.PULL_UP_RESISTANCE.R_2K2 , S_i_InternalPullDownResistance:=EPEC_HW.PULL_DOWN_RESISTANCE.R_82K , S_i_OutputResistanceHigh:=DINT#1400 , S_i_OutputResistanceLow:=DINT#843 , S_i_DiagnosticDelay:=UINT#1000 , i_pEventCode:=ADR(S_Inputs.o_EventCodeMain_LinearTempSensor) );

|

Validation init with SafeDataValidation V1.0.0.7Validation init with SafeDataValidation V1.0.0.7

|

Init method:

TemperatureValueDiagnostic.Init( S_i_HighErrorLimit:=DINT#100 , S_i_LowErrorLimit:=DINT#-5 , S_i_EnableHighError:=TRUE , S_i_EnableLowError:=TRUE , S_i_DiagnosticDelay:= UINT#1000, S_i_SafeOutputValue:= DINT#0, i_pEventCode:=ADR(S_Inputs.o_EventCodeMain_KTYTempSensor) );

END_IF |