Supported platforms: CODESYS 3.5, CODESYS 3.5 SAFETY, CODESYS 3.5 SP19 SAFETY

This function converts resistance value to temperature (°C). POU’s operational range is from -50°C to 150°C.

This function can be used for KTY type temperature sensor such as KTY1000 and KTY2000.

The function has internal calibration curve with 9 calibration points which is used in calibration.

Between 2 consecutive calibration points the curve is assumed to be linear.

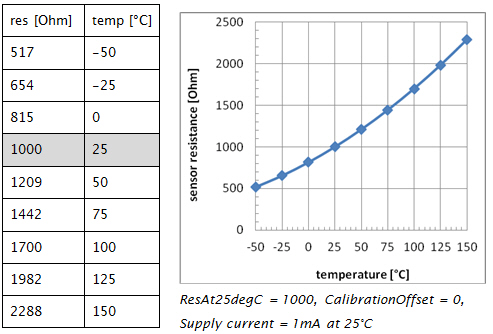

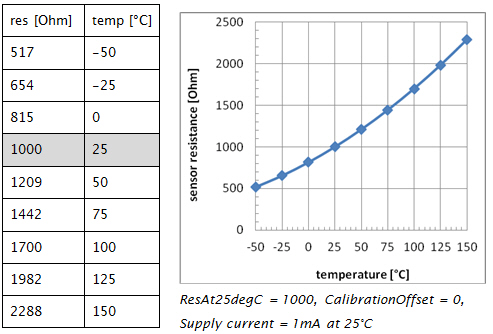

Figure 5-2. Calibration curve points.

The calibration curve is calculated from equation 1

![]()

, where R25 = resistance at 25°C, T = temperature, α = 7,88*10-3 and β = 1,937*10-5.

The equation is taken from Infineon Technologies KTY sensor specification. The calibration curve is not necessary exactly identical to some other manufacturer's KTY sensors. The input parameters S_i_ResistanceAt25degC and S_i_CalibrationOffset can be used to tune the curve so that it is accurate enough in most cases. S_i_ResistanceAt25degC defines the sensor resistance value at 25°C and S_i_CalibrationOffset shifts the calibration curve linearly up or down.

|

|

Sensor hardware errors are diagnosed with SafeConversion library's function blocks S_ADCToVoltageOrCurrent or S_VoltageToResistance. |

|

|

Sensor value alarms and warnings are diagnosed with SafeDataValidation library function block S_ValueDiagnostic. |

|

Input variable name |

Data type |

Unit |

Range |

Description |

|

S_i_SensorResistance |

SAFEDINT |

mΩ |

> 0 |

KTY sensor resistance. If value < 0 then resistance value 0 is used internally. |

|

S_i_ResistanceAt25degC |

SAFEUDINT |

mΩ |

> 0 |

Sensor’s typical resistance value at 25°C. If value is 0 then default value 1000000 (1000 Ω) is used internally. |

|

S_i_CalibrationOffset |

SAFEDINT |

mΩ |

- |

Resistance offset value for fine tuning calibration curve |

|

Data type |

Unit |

Range |

Description |

|

SAFEDINT |

°C |

-50 – (+)150 |

Measured sensor temperature. |

No errors.

|

|

This example contains the validation of 2 KTY sensors voltage signals, conversion from voltage to temperature and the diagnostic of temperature value . |

|

Safe definitions: |

|

PROGRAM S_TemperatureKTY VAR_INPUT S_i_SafetySystemEnable: SAFEBOOL := FALSE; i_KTY_A: SAFEDINT := DINT#0; (*KTY A sensor voltage signal mV*) i_KTY_A_Pullup: SAFEDINT := DINT#0; (*KTY sensor reference voltage mV *) i_KTY_B: SAFEDINT := DINT#0; (*KTY B sensor voltage signal mV*) i_KTY_A_Status: EPEC_SC.Status; (*KTY A sensor voltage signal status*) i_KTY_A_Pullup_Status: EPEC_SC.Status; (* Reference voltage status *) i_KTY_B_Status: EPEC_SC.Status; (*KTY B sensor voltage signal status*) i_pEventCodeKTY_A: POINTER TO EPEC_DITF.EventCode := DWORD#0; i_pEventCodeKTY_B: POINTER TO EPEC_DITF.EventCode := DWORD#0; END_VAR VAR_OUTPUT o_S_Temperature: SAFEDINT; o_TemperatureStatus: EPEC_SDV.Status; END_VAR

VAR initDone: BOOL; validationEnable: BOOL; S_ValidatedVoltage: SAFEDINT; S_ValidatedResistance: SAFEDINT; S_Temperature: SAFEDINT; validation_status: EPEC_SDV.Status; resistance_status: EPEC_SC.Status; S_KTYValidation: EPEC_SDV.S_ValidateAI; S_KTYResistance: EPEC_SC.S_VoltageToResistance; S_KTYDiagnostics: EPEC_SDV.S_ValueDiagnostic; END_VAR VAR CONSTANT S_AI_TOLERANCE: SAFEDINT := DINT#100; S_KTY_RES_AT_25C: SAFEUDINT := UDINT#2000000; S_KTY_NO_OFFSET: SAFEDINT := DINT#0; END_VAR |

|

Init at safe PRG: |

|

IF NOT initDone THEN initDone := TRUE;

S_KTYValidation.Init( S_i_InvertedCh2 := FALSE, S_i_DiagnosticDelay := EPEC_HW.Constants.G_VOLTAGE_INPUT_DIAGNOSTIC_DELAY, S_i_SafeOutputValue := EPEC_HW.Constants.G_VOLTAGE_INPUT_SAFE_VALUE, S_i_Tolerance := S_AI_TOLERANCE, S_i_SumValue := DINT#0, i_pEventCode := i_pEventCodeKTY_A, i_pEventCodeCh2 := i_pEventCodeKTY_B );

S_KTYResistance.Init( S_i_InternalPullUpResistance := EPEC_HW.PULL_UP_RESISTANCE.R_2K2, S_i_InternalPullDownResistance := EPEC_HW.PULL_DOWN_RESISTANCE.R_82K, S_i_OutputResistanceHigh := DINT#4500, S_i_OutputResistanceLow := DINT#1000, S_i_DiagnosticDelay := UINT#1000, i_pEventCode := i_pEventCodeKTY_A ); S_KTYDiagnostics.Init( S_i_HighErrorLimit := DINT#100, S_i_LowErrorLimit := DINT#-5, S_i_EnableHighError := TRUE, S_i_EnableLowError := TRUE, S_i_DiagnosticDelay := UINT#1000, S_i_SafeOutputValue := DINT#0, i_pEventCode := i_pEventCodeKTY_A );

END_IF

|

|

Code at safe PRG: |

|

|

Source file topic100408.htm

Last updated 4-Sep-2025