|

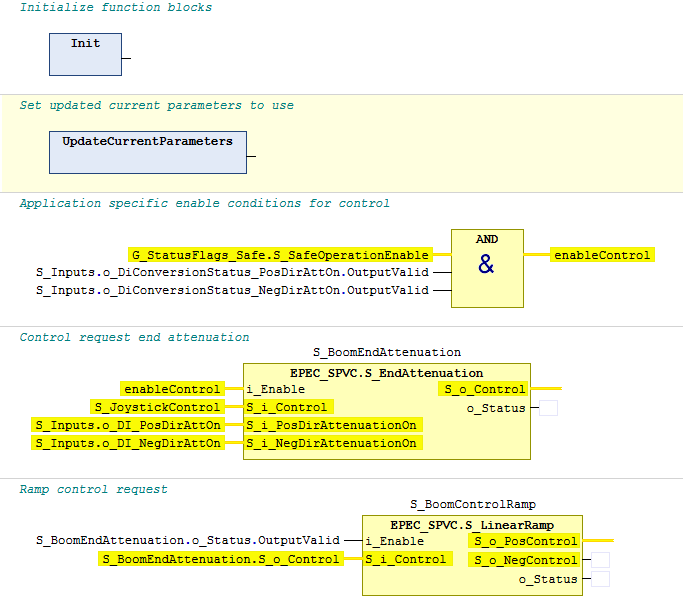

IF NOT initDone THEN

initDone:=TRUE;

(*Application specific parameters*)

(*ec_controlUp can be replaced with Joystick's event code if it exists in same control unit*)

S_BoomEndAttenuation.Init(

S_i_PosDirAttenuationLimit := UINT#90,

S_i_NegDirAttenuationLimit := UINT#90,

i_pEventCode := ADR(ec_controlUp),

i_pEventCodePosDirAtt := ADR(S_Inputs.o_EventCode_PosDirAttOn),

i_pEventCodeNegDirAtt := ADR(S_Inputs.o_EventCode_NegDirAttOn)

);

S_BoomControlRamp.Init(

S_i_PosDirAscendRampTime := UINT#1000,

S_i_PosDirDescendRampTime := UINT#1000,

S_i_NegDirAscendRampTime := UINT#1000,

S_i_NegDirDescendRampTime := UINT#1000,

S_i_EnableCounterControl := FALSE,

i_pEventCode := ADR(ec_controlUp)

);

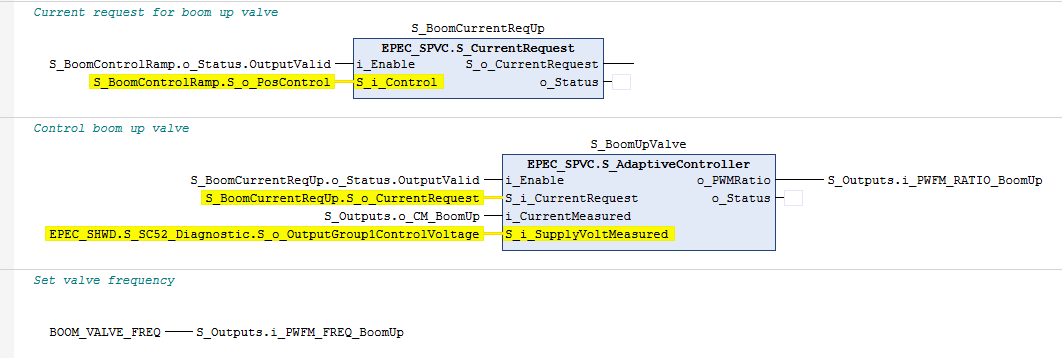

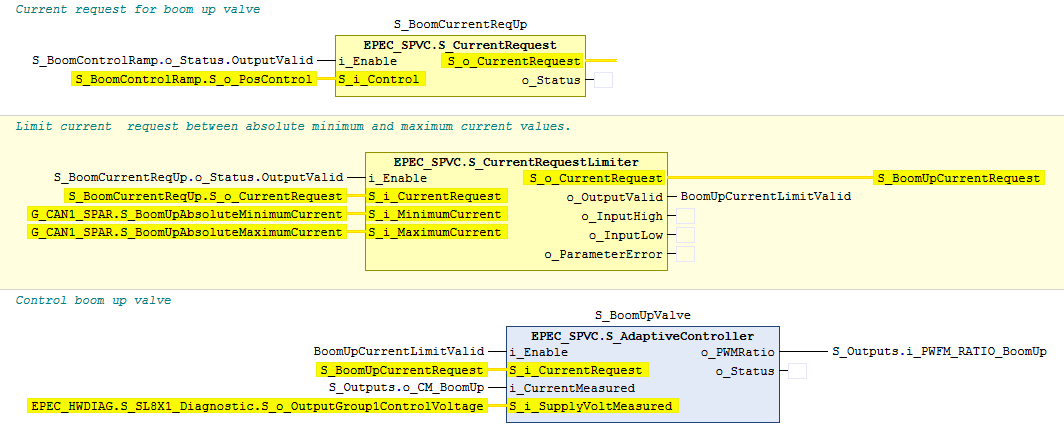

// Note! The minimum and maximum current paremeters can be non-safety parameters

S_BoomCurrentReqUp.Init(

S_i_MinimumCurrent := G_CAN1_PAR.BoomUpMinimumCurrent,

S_i_MaximumCurrent := G_CAN1_PAR.BoomUpMaximumCurrent,

S_i_PositiveControlDir := TRUE,

i_pEventCode := ADR(ec_controlUp)

);

S_BoomUpValve.Init(

S_i_CoilResistance := UDINT#22000,

S_i_OverCurrentLimit := UINT#1100,

S_i_WireBrokenLimit := UINT#50,

S_i_DiagnosticDelay := UINT#100,

i_pCorrectionParameters := ADR(ccParams),

i_pImpulseUpParameters := ADR(ccParamsImpUp),

i_pImpulseDownParameters := ADR(ccParamsImpDown),

S_i_ParameterCount := S_CURRENT_CONTROLLER_PAR_COUNT,

S_i_ParStep := S_CURRENT_CONTROLLER_PAR_STEP,

i_pEventCode := ADR(ec_controlUp)

);

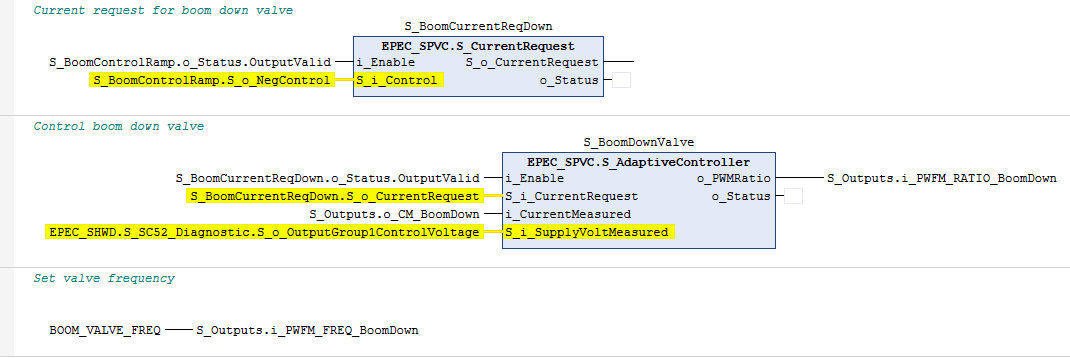

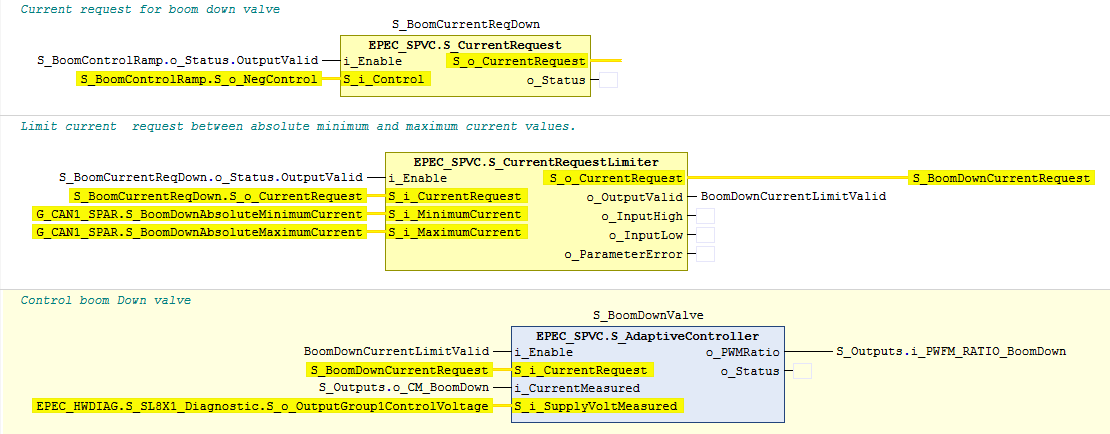

// Note! The minimum and maximum current paremeters can be non-safety parameters

S_BoomCurrentReqDown.Init(

S_i_MinimumCurrent := G_CAN1_PAR.BoomDownMinimumCurrent,

S_i_MaximumCurrent := G_CAN1_PAR.BoomDownMaximumCurrent,

S_i_PositiveControlDir := FALSE,

i_pEventCode := ADR(ec_controlDown)o_

);

S_BoomDownValve.Init(

S_i_CoilResistance := UDINT#22000,

S_i_OverCurrentLimit := UINT#1100,

S_i_WireBrokenLimit := UINT#50,

S_i_DiagnosticDelay := UINT#100,

i_pCorrectionParameters := ADR(ccParams),

i_pImpulseUpParameters := ADR(ccParamsImpUp),

i_pImpulseDownParameters := ADR(ccParamsImpDown),

S_i_ParameterCount := S_CURRENT_CONTROLLER_PAR_COUNT,

S_i_ParStep := S_CURRENT_CONTROLLER_PAR_STEP,

i_pEventCode := ADR(ec_controlDown)

);

END_IF

|

![]()