|

IF bInit THEN

bInit := FALSE;

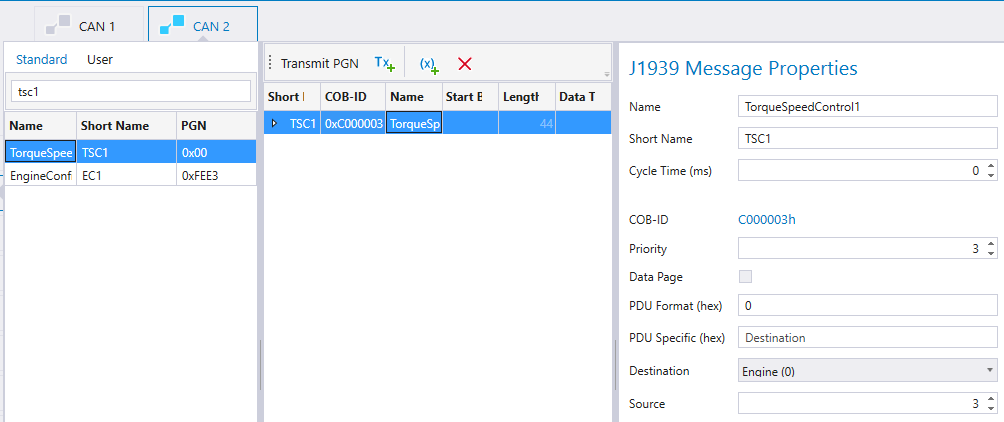

(* Set TSC1 PGN *)

(* Time triggered CAN message supports only data length <= 8 *)

IF J1939_CAN2.Out.Engine.PGN_TSC1.DataLength <= 8 THEN

(* Set cycle time to 0ms to prevent message sending by J1939 server *)

J1939_CAN2.Out.Engine.PGN_TSC1.CycleTime := 0;

(* Set data length *)

tsc1CanApiHandler.i_Dlc := WORD_TO_BYTE(J1939_CAN2.Out.Engine.PGN_TSC1.DataLength);

(* Set init data for message *)

EPEC_J1939.J1939_BuildPGN(

i_pBasePGN := ADR(J1939_CAN2.Out.Engine.PGN_TSC1),

i_pDataBuffer := ADR(tsc1CanApiHandler.i_Data)

);

(* Init cobid for time triggered message *)

(* build used cobid from PGN *)

usedCobId:=BYTE_TO_DWORD(J1939_CAN2.Out.Engine.PGN_TSC1.Priority);

usedCobId:=SHL(usedCobId,1) OR 0;

usedCobId:=SHL(usedCobId,1) OR BYTE_TO_DWORD(J1939_CAN2.Out.Engine.PGN_TSC1.DataPage);

usedCobId:=SHL(usedCobId,8) OR WORD_TO_DWORD(SHR(J1939_CAN2.Out.Engine.PGN_TSC1.PGN_Number,8) AND 16#FF);

IF 16#F000 > J1939_CAN2.Out.Engine.PGN_TSC1.PGN_Number THEN

usedCobId:=SHL(usedCobId,8) OR BYTE_TO_DWORD(J1939_CAN2.Out.Engine.PGN_TSC1.Destination);

ELSE

usedCobId:=SHL(usedCobId,8) OR WORD_TO_DWORD(J1939_CAN2.Out.Engine.PGN_TSC1.PGN_Number AND 16#FF);

END_IF

usedCobId := SHL(usedCobId,8) OR BYTE_TO_DWORD(J1939_CAN2.Out.Engine.PGN_TSC1.SourceAddress);

usedCobId := usedCobId OR EPEC_CANVXD.MASK_29BIT; (* Set bit on which defines message as 29bit *)

(* Init time triggered message *)

tsc1CanApiHandler.InitCobId(

i_CanChannel := 1, (*CAN2*)

i_CobId := usedCobId,

i_TimeInterval := T#10MS

);

tsc1CanApiHandler.i_Enable := TRUE;

END_IF

ELSE

(* J1939 variables are accessed normally through J1939 structure*)

J1939_CAN2.Out.Engine.TSC1_EngRqedSpeed_SpeedLimit := WORD#1000 * 8; (*1000 rpm to raw value*)

(* Update PGN data to Api handler input*)

EPEC_J1939.J1939_BuildPGN(

i_pBasePGN := ADR(J1939_CAN2.Out.Engine.PGN_TSC1),

i_pDataBuffer := ADR(tsc1CanApiHandler.i_Data)

);

(* Function block instance must be called at least with 100ms interval *)

tsc1CanApiHandler();

END_IF

|

![]()